HIWIN’s core competence is to offer Complete mechatronic system integration. HIWIN provides pre-sales to after sales product life cycle service, covering from customer product design, evaluation, selection and maintenance service.

With innovative and reliable product, HIWIN offers total solution and value added to its customers in improving the machining productivity and competitiveness.

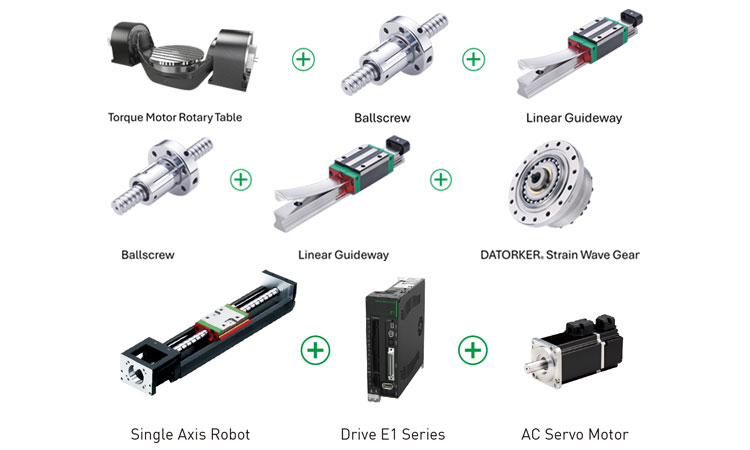

5-axis machining – Total Solution

The Torque Motor Rotary Table ensures high dynamic performance and accurate positioning, ideal for complex machining tasks, with rapid response speeds that enhance productivity. Paired with HIWIN’s high-precision Ballscrew, this solution guarantees exceptional feed accuracy and reliability, meeting the stringent requirements of modern manufacturing.

HIWIN’s Guideways provide excellent load capacity and stability, reducing friction and wear for extended service life. This integrated solution not only maximizes productivity and minimizes downtime but also addresses the industry’s need for high-quality components that improve machining performance, drive innovation, and ensure competitive advantage

Cutting machine Total Solution

HIWIN’s ballscrews, linear guideways, and DATORKER® Strain Wave Gear are engineered to deliver exceptional performance and stability in cutting machine applications, tailored to meet precision machining demands. HIWIN ballscrews provide high-accuracy feed control, ensuring precise positioning and efficiency throughout the cutting process, ideal for high-demand machining tasks. HIWIN linear guideways enhance stability with a high-rigidity support system that reduces vibration-induced errors during machining, resulting in products with superior accuracy and quality. Paired with HIWIN DATORKER® Strain Wave Gear, these core components play a pivotal role in power transmission and cutting force control, boosting stability, extending equipment lifespan, and optimizing overall machining performance.

Drilling machinesTotal Solution

HIWIN’s Total Solution for drilling machines combines the KK Single Axis Robot, AC servo motors, and E1 drives, specifically designed to meet the high-efficiency drilling demands of various industries, particularly automotive, aerospace, electronics, and heavy machinery.

The KK Single Axis Robot features an integrated design of the ballscrew nut and linear guideway, offering high precision, high rigidity, and space-saving advantages. This allows for the precise execution of various drilling tasks, easily handling both small components and large workpieces. Coupled with high-performance AC servo motors, it provides rapid response and high torque output, ensuring exceptional machining accuracy and consistency even at high speeds. The E1 drive utilizes advanced control technology to deliver smooth motion control, enhancing system reliability and stability.

Choosing HIWIN as your partner for upgrade and transformation means gaining access to a wealth of expertise and innovative solutions tailored to meet the unique needs of your industry. HIWIN’s total solutions and services will help you enhance productivity, improve competitiveness, and achieve long-term success.

For more information,

www.hiwin.tw