Bearings are the silent workhorses of modern industry, enabling machines to run smoothly, efficiently, and reliably. They find application in sectors as diverse as automotive, aerospace, railways, energy, defense, agriculture, and construction equipment. What distinguishes a high-performance bearing from an ordinary one is not just the material or design, but the precision with which it is manufactured. At the heart of this precision lies metrology—the science of measurement. Metrology ensures that every component of a bearing is produced within the strictest dimensional tolerances and surface quality requirements, thereby guaranteeing performance, reliability, and longevity.

Why Metrology Matters in Bearings

A bearing’s function is deceptively simple: to reduce friction between moving parts and to carry loads. Yet, the physics governing this function are highly sensitive to dimensional and geometrical accuracy. Even microscopic deviations in roundness, surface finish, or alignment can lead to excessive friction, vibration, heat generation, and ultimately premature failure.

For example, a deviation as small as a few microns in a raceway groove can change the stress distribution dramatically, shortening the bearing’s life. Metrology provides the tools and techniques to measure and control such variations, ensuring that bearings meet exacting standards before they reach the customer.

Dimensional Accuracy and Tolerances

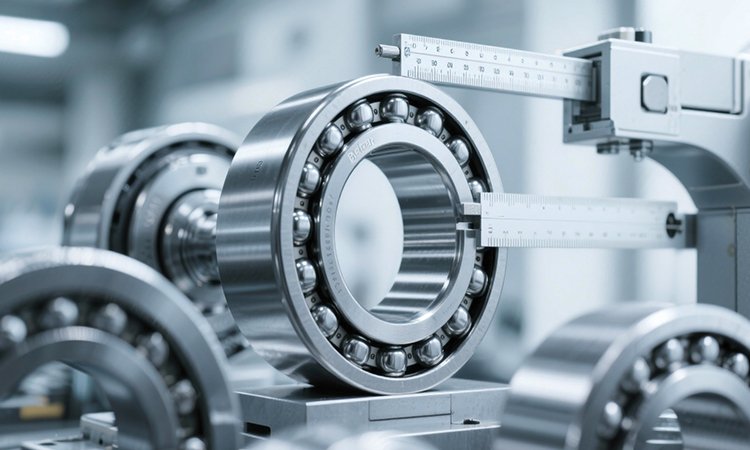

One of the most critical aspects in bearing manufacture is achieving precise dimensional tolerances. Components such as inner rings, outer rings, and rolling elements must fit together with perfect harmony. The diameters, widths, and raceway geometries are measured to sub-micron accuracy. High-precision coordinate measuring machines (CMMs), laser interferometers, and air gauges are used to check dimensions consistently.

Bearings are often classified into tolerance classes—such as P5, P4, or even P2 for high-precision applications—each requiring progressively tighter tolerances. Meeting these classes is impossible without advanced metrological controls.

Geometric Accuracy: Roundness and Cylindricity

The performance of bearings is critically dependent on geometric properties such as roundness, cylindricity, and concentricity. Roundness testers and form measuring instruments are employed to ensure that rolling elements (balls or rollers) are perfectly spherical or cylindrical.

Any deviation leads to uneven load distribution, resulting in noise, vibration, and accelerated wear. Similarly, concentricity of the inner and outer rings is verified to ensure that the bearing rotates smoothly without eccentric motion.

Surface Finish and Roughness Measurement

Surface quality is another crucial dimension where metrology plays a vital role. The rolling contact surfaces of rings and rolling elements must be smooth to the nanometer scale to minimize friction and wear. Surface roughness testers measure parameters such as Ra (average roughness) and Rz (mean peak-to-valley height).

For high-speed or aerospace bearings, advanced optical profilometers and white light interferometers are used to characterize the surface in three dimensions. Consistent surface finish ensures stable lubrication film formation, reducing the risk of scuffing or pitting during operation.

Hardness and Microstructural Integrity

While dimensional and surface accuracy are paramount, the mechanical properties of the material must also be verified. Metrology extends into materials testing through hardness measurement, microstructure analysis, and residual stress evaluation.

Microhardness testers check the heat-treated rings and rolling elements to confirm they meet the required hardness for fatigue resistance. Non-destructive methods such as ultrasonic or magnetic particle inspection are employed to detect subsurface flaws that could compromise bearing performance.

Role of Automation and In-line Metrology

With the growing demand for mass production of bearings, manufacturers are increasingly integrating automated metrology systems into production lines. In-line measurement systems, equipped with contact and non-contact sensors, continuously monitor critical dimensions during machining and grinding. This reduces rejection rates, minimizes rework, and ensures that defects are caught early. The integration of robotics with metrology has further enhanced throughput, allowing real-time data collection without interrupting production.

Metrology in Superfinishing and Honing

After grinding, bearing components often undergo superfinishing and honing to achieve mirror-like surface finishes and fine geometric corrections. Metrology ensures that these processes achieve their intended results. For instance, measuring waviness and micro-texture helps in predicting the bearing’s frictional behavior and noise performance. The correlation between superfinished surfaces and vibration-free operation in applications such as electric vehicle drivetrains highlights the importance of precise surface metrology.

Measuring Lubrication Gaps and Clearances

Another area where metrology is critical is in verifying internal clearances and lubrication gaps. Bearings must maintain the right clearance to accommodate thermal expansion and load-induced deformation while still ensuring effective lubrication. Precision gauges and clearance measurement systems are used to confirm radial and axial clearances. In high-precision aerospace bearings, even preload measurements are carried out using advanced metrological techniques to guarantee stability during flight.

Digital Metrology and Industry 4.0

The digitalization of metrology has opened new frontiers in bearing manufacture. Smart sensors, IoT-enabled measurement devices, and cloud-based data analytics now enable real-time monitoring and process control. Digital twins of manufacturing processes are created, allowing engineers to simulate variations in tolerances and predict their impact on bearing performance. The use of machine learning in analyzing metrology data also helps in predictive quality control, where potential defects are flagged before they materialize.

Traceability and Standards

Metrology is also central to ensuring traceability and compliance with international standards such as ISO 492 and ISO 199. Calibration of measuring instruments against national standards ensures consistency across production sites and supply chains. This traceability is particularly vital for bearings used in safety-critical applications such as aerospace engines, railway bogies, or medical devices, where failure can have catastrophic consequences.

Challenges in Bearing Metrology

Despite significant advancements, bearing metrology presents unique challenges. Achieving sub-micron accuracy in high-volume production environments demands robust, repeatable measurement systems. Thermal effects, machine vibrations, and operator influence must be minimized. Additionally, the increasing use of advanced materials such as ceramics requires specialized metrology solutions to characterize hardness, porosity, and micro-defects that differ from traditional steel bearings.

Future of Metrology in Bearing Manufacture

Looking ahead, metrology in bearing manufacture is expected to become even more intelligent, automated, and integrated. Non-contact optical and X-ray techniques are being developed to measure hidden features and subsurface defects. Nanometrology will play a larger role as ultra-precision bearings are required for applications such as semiconductor manufacturing and space exploration. The convergence of metrology with AI, robotics, and digital manufacturing promises a future where bearing quality is assured with unprecedented accuracy and efficiency.

Conclusion

Metrology is not just a support function in bearing manufacture—it is the backbone of quality and reliability. From ensuring dimensional accuracy and geometric precision to guaranteeing surface quality and material integrity, metrology underpins every stage of bearing production. As industries demand higher speeds, greater loads, and longer service lives from their bearings, the role of metrology will only grow in significance. By harnessing advanced measurement technologies and integrating them with digital manufacturing, bearing manufacturers can continue to deliver products that meet the world’s highest standards of performance and safety.