igus Fixed Flange Bearings Become Intelligent

New Generation Of Igubal Spherical Bearings Is Equipped With Predictive Maintenance System

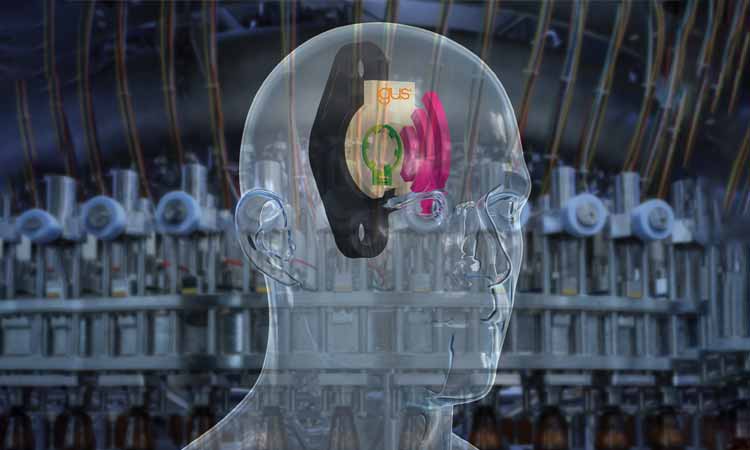

Expensive machine and vehicle breakdowns due to undetected faults in heavy-duty fixed flange bearings: these will soon be a thing of the past thanks to a new generation of two- and four-hole fixed flange bearings. Their special feature is that the bearings, which are made of lubrication-free high-performance plastic, are equipped with miniature wireless sensors, enabling condition monitoring and predictive maintenance.

A technician looks at his smartphone: a conveyor belt of a beer bottle discharge system contains a fixed flange bearing that is approaching its wear limit. Previously, the problem might not have been detected and cause an expensive system failure. Today, however, the technician can simply replace the bearing during a break in production – knowing definitely that the hundreds of other bearings also communicate with him. “This scenario is no longer science fiction. As part of our smart plastics range, we are gradually equipping plain bearings made of high-performance plastics with networked sensors,” says Thomas Preißner, Head of Business Unit igubal Spherical Bearings at igus. “Our two- and four-hole fixed flanged bearings from the igubal series now also enable condition monitoring and predictive maintenance to prevent unforeseen damage.”

Flange bearings transmit their status wirelessly

And this is how the new Industry 4.0 bearings work: igus integrates an abrasion sensor into the polymer spherical ball: a thin circuit board close to the running surface. There is also a battery for the power supply without cables. This means that the bearing for spherical levelling can continue to move independently. Wear interrupts the conductor paths of the circuit board. If the electronics lose the signal of a conductor path, they know that the wear has reached a certain level. The sensor transmits a digital signal via a long-range network (LoRa), a wireless standard for the Internet of Things that is known for its energy efficiency. The receiver is the i.Cee switch cabinet module, which analyses the data. The associated software now knows that the conductor path is worn out, and infers the percentage of abrasion. Over time, the sensor itself wears away layer by layer – parallel to the bearing’s running surface. It continues to send out signals that allow conclusions to be drawn regarding the bearing’s condition. Users can see the remaining service life and when maintenance is due on a web-based dashboard, which they can access from anywhere in the world with a PC, tablet or smartphone.

Luxembourg’s national railway company is the first pilot customer for smart fixed flange bearings

The new fixed flange bearings are currently in the prototype phase. However, they have already convinced one pilot customer: the Société National des Chemins de Fer Luxembourgeois (CFL). Luxembourg’s national railway company operates a 200-metre washing system that cleans local and long-distance trains every day. In the past, gearbox malfunctions on the washing trolley repeatedly led to costly system failures. The operator therefore abandoned lubricated standard ball bearings and instead used the networked spherical balls from igus in the UC bearing housings. The advantage is that the spherical balls made of high-performance plastics are corrosion-free, resist chemicals and enable low-friction and maintenance-free dry operation thanks to incorporated solid lubricants. “The other bearings have to be lubricated every few weeks, which is very time-consuming,” says CFL Maintenance Manager Mike Feinen. “We have therefore ticked off this maintenance issue.” Says Thomas Preißner: “The new networking feature puts the icing on the cake. Thanks to continuous condition monitoring, CFL can prevent failures, plan maintenance work ideally and make full use of the polymer bearings’ service life.”

Find out more about smart condition monitoring and predictive maintenance in the train washing system from CFL here:

https://www.igus.in/info/smart-plastics-train-washing

ABOUT IGUS:

igus GmbH develops and produces motion plastics. These lubrication-free, high-performance polymers improve technology and reduce costs wherever things move. In energy supplies, highly flexible cables, plain and linear bearings as well as lead screw technology made of tribo-polymers, igus is the worldwide market leader. The family-run company based in Cologne, Germany, is represented in 31 countries and employs 4,600 people across the globe. In 2022, igus generated a turnover of €1,15billion. Research in the industry’s largest test laboratories constantly yields innovations and more security for users. 234,000 articles are available from stock and the service life can be calculated online. In recent years, the company has expanded by creating internal startups, e.g. for ball bearings, robot drives, 3D printing, the RBTX platform for Lean Robotics and intelligent “smart plastics” for Industry 4.0. Among the most important environmental investments are the “chainge” programme – recycling of used e-chains – and the participation in an enterprise that produces oil from plastic waste.

For more information

igus®(India) Private Limited

www.igus.eu