Materials handling equipment is essential in various industries for the efficient movement, storage, control, and protection of materials and products throughout the manufacturing, distribution, consumption, and disposal processes. Bearings play a critical role in the functionality and reliability of these machines. This article delves into the types of bearings used in materials handling equipment, their applications, benefits, and considerations for selection.

Types of Bearings

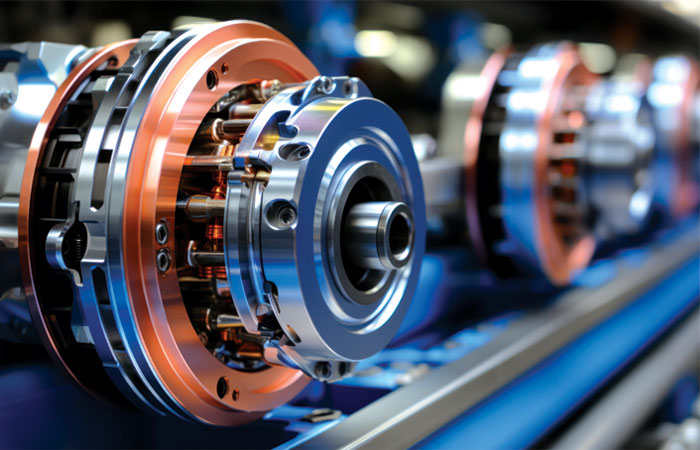

Ball Bearings:

Description: Composed of balls that are sandwiched between two “races” or rings. They are designed to reduce rotational friction and support radial and axial loads.

Applications: Commonly used in conveyor belts, electric motors, and gearboxes.

Benefits: High-speed capability, low friction, and longevity.

Roller Bearings:

Description: Utilize cylindrical rollers instead of balls, providing a larger contact area with the races.

Applications: Ideal for heavy-duty applications such as pallet jacks, forklifts, and cranes.

Benefits: Can handle higher load capacities compared to ball bearings, suitable for both radial and axial loads.

Thrust Bearings:

Description: Designed specifically to handle axial loads, they consist of two washers with rolling elements in between.

Applications: Used in applications where axial load support is crucial, such as in lift tables and scissor lifts.

Benefits: High load capacity in the axial direction, durability under heavy axial forces.

Needle Bearings:

Description: A type of roller bearing with long, thin cylindrical rollers.

Applications: Compact spaces and light machinery like hand trucks and small conveyors.

Benefits: High load capacity with a small cross-section, suitable for oscillating applications.

Spherical Bearings:

Description: Have an inner ring with two raceways that allows angular misalignment.

Applications: Heavy machinery where shaft alignment might be an issue, such as in large conveyor systems.

Benefits: Can accommodate misalignment, robust and durable under heavy loads.

Applications in Materials Handling Equipment

Conveyors: Bearings facilitate smooth and efficient movement of conveyor belts, reducing friction and wear.

Forklifts: Critical for mast operation, steering, and drive components, enabling reliable lifting and maneuvering.

Cranes: Bearings support rotation and load handling capabilities, crucial for both overhead and mobile cranes.

Automated Guided Vehicles (AGVs): Bearings ensure precise movement and operation, enhancing automation efficiency.

Pallet Jacks and Stackers: Bearings in wheels and lifting mechanisms enhance load-bearing capacity and maneuverability.

Benefits of Using Bearings

Reduced Friction: Bearings minimize friction between moving parts, leading to smoother operation and less wear.

Load Capacity: They provide the ability to handle both radial and axial loads, depending on the type of bearing.

Durability: Bearings are designed to withstand harsh operating conditions, including heavy loads, high speeds, and adverse environments.

Maintenance and Reliability: Properly selected and maintained bearings can extend the lifespan of equipment, reducing downtime and maintenance costs.

Selection Considerations

- Load Requirements: Determine whether the application requires handling of radial, axial, or combined loads.

- Speed: Consider the operating speed of the equipment to choose bearings that can handle the desired speed without overheating or excessive wear.

- Environment: Assess environmental factors such as temperature, humidity, and exposure to contaminants which may impact bearing performance.

- Space Constraints: Evaluate the available space for bearing installation to ensure compatibility with the equipment design.

- Alignment: Account for potential misalignment issues that might necessitate the use of specific types of bearings like spherical bearings.

Conclusion

Bearings are integral to the efficiency and reliability of materials handling equipment. By understanding the types of bearings available and their respective applications, industry professionals can make informed decisions to enhance operational performance and extend the lifespan of their machinery. Proper selection, maintenance, and monitoring of bearings can lead to significant improvements in the productivity and safety of materials handling processes.