TEXSPIN® An indomitable global player in the automotive sector

TEXSPIN Bearings ltd has revolutionized the automotive industry with cutting-edge solutions since 1961. A pioneer in bearing manufacturing to a knowledge-based, technology-driven enterprise, the transformation of TEXSPIN is quite pronounced, with its unwavering dedication to help customers achieve long-term, competitive business excellence. TEXSPIN’s technology solutions help automotive and industrial companies introduce innovative technology products and accomplish a long-term friction reduction, energy efficiency, and equipment longevity as well as dependability. TEXSPIN excels in bearing development, heat treatment, precision machining and measurement. The company offers tailor-made, value-added, solutions to its customer base across the globe.

Armed with two sprawling manufacturing facilities, four regional sales offices, 400 plus dealers, and 1,500 motivated and dedicated employees, TEXSPIN has established its prominent presence in major markets across the globe which include Europe, North America, South America, the Middle East, Asia, and Australia. Twenty per cent of its annual sales turnover comes from exports.

Managing Director, Dipen Makwana, is a third-generation entrepreneur who grew up in a family of business owners and who, after earning his degrees in Engineering and Business Management abroad and gaining work experience in the automobile industry overseas, has been deeply involved in the company’s strategic business management for more than a decade and is carrying out the founders’ vision by investing in state-of-the-art infrastructure and cutting-edge technologies. In an exclusive interview with Bearing Review, Dipen explains what makes TEXSPIN the numero uno, hinged to the fortunes of the thriving automotive sector. Excerpts:

Q. Is everything hunky-dory with the bearing industry?

In 2021, the market for bearings in India was worth between US$1.5 and US$1.7 billion; by 2027, it would be worth between US$3 and US$3.5 billion, expanding at a CAGR of 11% to 12%. In 2021, the global market for bearings was valued at over US$107 billion, and its value is anticipated to increase by 8% to 9%CAGR between 2022 and 2030.

Asia-Pacific accounted for 40% of sales in 2021. With engineering and automotive advancements and a robust aftermarket in industrial equipment and vehicle repair, this region may have the highest revenue growth by 2030, exceeding $100 billion. The robust construction and mining equipment industry in India should stimulate market expansion through 2030.

The European market can expand steadily as a result of economic expansion and growing investment. Demand in industrialized nations is also on the rise due to the automobile industry and anticipated economic expansion. The American market could benefit from high-quality bearings, such as large diameter custom bearings utilized in heavy machinery and wind turbines. Rapid urban infrastructure building in the Middle East and Africa is also driving economic expansion.

Q. What are the stimuli that will drive the growth of the industry?

The COVID-19 pandemic had disrupted numerous manufacturing enterprises in major economies. Supply chain delays and movement restrictions have reduced production in the automotive industry, which otherwise uses bearings in huge volumes. In the later part of 2020, limitations were eased and production resumed, improving the situation. The global rollout of coronavirus vaccinations boosted the market growth.

Despite the driving factors, the climactic uncertainties, high initial investments, and potential job loss are estimated to hinder market growth.

Growing demand for automotive electrification and increased use of bearing in motors: Modern cars aim for better overall cost of ownership, vehicle uptime, and optimal use. Bearings are essential for optimizing rotating parts. They reduce system noise. Modern bearings are more sophisticated and technologically advanced. Their use of efficient powertrains is rising. Thus, automobile electrification and motor bearings will grow the market.

Manufacturing-boosting government programs: The Indian government has policies and regulations in placed to ensure the manufacturing of safe products. The Bureau of Indian Standards, the Ministry of Heavy Industries & Public Enterprises, and the Ministry of Labour & Employment are three government institutions that support the country’s regulatory framework. They contribute to increased domestic production, export promotion, mandatory standardization of machines and equipment through adoption of ISO, technological advancement, reduced substandard imports via standardization, and skill development. All of these factors benefit the manufacturing sector, thereby fostering market expansion. Above all,, modern and futuristic initiatives like the Make in India and Production-Linked Incentive (PLI) Scheme in the automobile and auto components sectors. The PLI plan for the automotive sector offers financial incentives of up to 18% to increase domestic manufacturing of sophisticated automotive technology items and attract investments in the automotive manufacturing value chain.

India’s competitiveness as a market with a large consumer base and export hub has increased FDI over the past five to six years. FDI rose from USD 190 billion in 2009-10 to USD 284 billion in 2013-14 and 2018-19. The government’s commitment towards the Make in India initiative, economic stimulus, and infrastructure, power, oil and gas, airports, roads, and ports will provide ample opportunities for the economy’s driving industries.

Demand for passenger vehicles, commercial vehicles, and three-wheelers drives market growth. The market is driven by infrastructure demand and the growth of heavy, general, and other industries. Bearings are used in virtually every industry where dimensional accuracy is critical to performance. Revenue growth is expected from precision bearing demand in aerospace and related industries. Small industrial robot bearings will also be in demand. Technological advances in office automation, medical equipment, and audio-visual equipment will boost demand for these products. Growth comes from application-specific bearing development. As a result, more bearing manufacturers offer customized products. Custom bearings meet the needs of weaving looms, agricultural machinery, vacuum pumps, and turbochargers.

Q. What niche have you carved for yourself in this dynamic industry?

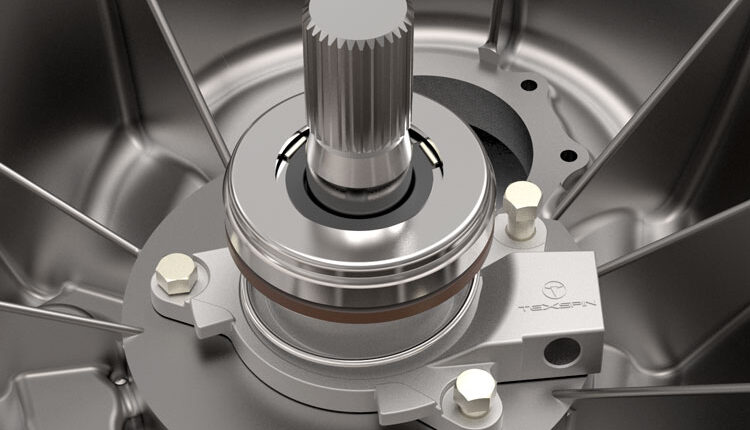

TEXSPIN® is known worldwide for its clutch release bearing solution, which makes up a large part of its product portfolio. We are one of the world’s leading suppliers of clutch release bearings, each of which is custom-designed. Our patented 3D self-centering clutch release bearing for automotive applications has accelerated technological development in this product category. The first-of-its-kind Hydro Pneumatic CSC from TEXSPIN® reduces clutch pedal effort for larger commercial vehicles and makes truck and bus driving fatigue-free. It also improves the clutch, master cylinder, release bearing, and other components’ durability, giving the client a lightweight, compact solution, among other benefits.

TEXSPIN® is one of a few global manufacturers of specialized, highly customized products for export and domestic markets. Wheel hub unit, patented Zero Drop Kingpin solution, pinion and differential bearing solution, 4-point contact zero clearance steering column bearing, detent pin, stamped synchronizer sets, stamped clutch body ring, and stamped one-way clutch are exclusive TEXSPIN® technological niche products.

TEXSPIN® is the leading suspension king pin bearing and shaft manufacturer and distributor in the domestic automotive industry. It has used its technical expertise and decades of research and development experience to develop the patent-protected “ZERO Drop Kingpin Assembly,” the most recent innovation in commercial vehicle axles. It enhances assembly life without maintenance. This technology reduces wheel jerks and wobbles, making driving more comfortable.

Q. The automotive industry is indeed on an upswing? What are the standard and customized solutions you offer to this sector?

Technological advances in seal and lubrication technologies are creating enormous opportunities for manufacturers. The integration of electro-mechanical components directly into bearings improves performance and reduces bearing size and cost. The development of the Internet of Things (IoT) has fostered the adoption of connected equipment and machinery.

Q. By overdependence on the automotive sector, are you not laying all the eggs in one basket?

TEXSPIN® and the automotive sector are intertwined. TEXSPIN®, as a provider of automotive technology solutions, cannot relinquish its foothold so simply; our decades of experience and role within the automotive sector are immaculate. Given that our contributions to the automotive industry are substantial and that we are continually enhancing our parts-per-vehicle offering, it is imperative that we continue to expand our market share. We are also investing for tomorrow’s needs today, and we are certain that we will deliver the appropriate solution to our business partners at the right moment for a win-win situation.

Automotive represented 49% of the economy in 2021. This sector is dominated by global auto production. Demand for technologically advanced vehicles, which require instrumented solutions, is also driving the growth of automobile manufacturing. Due to increased demand for high-tech automobiles and increased vehicle capacity, bearings have become more important in the automotive sector. The automotive aftermarket is predicted to grow at a greater CAGR, bolstering bearing demand.

Railways and aviation will lead transport growth by 2030. This growth is driven by the need to replace ageing fleets due to environmental regulations, rising fuel prices, and technology that improves global and local transportation systems. More developing countries building railways will boost the need for them. Single-aisle aircraft and helicopters in emerging economies will boost the business.

Companies like TEXSPIN® invest heavily in R&D to improve bearing quality and performance for specific applications. Strategic alliances, acquisitions, collaborations, and capacity expansions also boost market presence and client bases. Due to market competitiveness, companies are improving products and expanding facilities.

Automotive and industrial segments generate demand for bearings. TEXSPIN® is well-known in the automobile sector and is expanding into the industrial sector. TEXSPIN® is a global organization, but let’s assess opportunities in India.

Indian automotive bearing market: India’s Commercial Vehicle (CV) market, a direct measure of economic activity, is expected to expand by 2.97 % between 2018 and 2030. India is likely to lead the CV industry due to government incentives, a strong supplier ecosystem, raw materials, and a trained workforce.

Industrial Bearing Market: Indian industrial growth is crucial. Manufacturing revival and GDP growth are government priorities. Indian Railways wants better service. Its high-speed age is cutting logistics expenses and advancing modern production. Numerous global firms have invested in India and established manufacturing plants due to several planned rail projects in key cities.

Q. How do you partake in nation-building, by making the country self-reliant in bearings?

TEXSPIN®’s success has been distinguished by its pursuit of new ideas and technology to create unique solutions, which makes the emerging nation stronger and more courageous. This is supported by a research and development center that consistently creates industry-leading technologies. Our R&D center has cutting-edge software to simulate, analyze, validate, test, and design systems for various applications. TEXSPIN®’s reputation and performance are based on a deep understanding of product design, engineering, and technical innovation. Our innovations and creativity will promote TEXSPIN®. The TEXSPIN® R&D Center wants to be your development partner, a symbiotic relationship, and a thinking partner in developing unique and new technology solutions. To bring innovative ideas to life, we combine product design, analysis, prototyping, tooling, testing, validation, and mass production. Professionals handle each project’s activities, requirements, progress, and solutions cohesively.

TEXSPIN® designs and builds solutions for clients using internal combustion engines, hybrids, and all-electric powertrains based on its vehicle system knowledge. Hydrogen and fuel cell technology also offer a bright future for transportation. As vehicles become autonomous and driving functions become automated, chassis applications are in high demand. TEXSPIN®, a trusted technology partner, is expanding its component and system operations with security and dependability in mind. Research and development are also needed. TEXSPIN® will change the future of mobility by entering a new mobility sector.

Global-altering events seldom happen. We’re working to fix the situation because creative forces are more crucial to a company’s success than ever. Progress is usually marked by attention to detail and the realization that big things are made of many little parts. Our founder’s inventiveness and perseverance led to our success. We focus on future technologies and lay the groundwork for innovation to boost global transportation. Mobility is the only guarantee of progress.